GE applies Lean methods to tackle engine shortages

Anabelle Colaco

16 Feb 2026

SINGAPORE: Facing mounting jet engine repair backlogs across the aviation industry, GE Aerospace is turning to automation and "Lean" manufacturing techniques to speed up maintenance and ease supply bottlenecks.

At GE's repair facility in Singapore, technician Suresh Sinnaiyan, who has spent more than a decade manually restoring jet-engine compressor blades, is now training a robot to replicate the delicate sanding work once done entirely by hand.

The move forms part of GE's broader effort to relieve pressure on overloaded repair shops and scarce parts supplies, as unexpected wear in newer-generation engines has grounded aircraft and forced airlines to keep older jets flying longer.

Airlines have publicly criticised engine makers, arguing that shortages have led to higher prices, while manufacturers say they are investing heavily to expand support after absorbing steep development costs.

"They have got to remember airlines are their future and treat us as partners," AirAsia co-founder Tony Fernandes told Reuters, referring to the industry overall.

Singapore: The Pressure Valve

GE's Singapore hub, which employs about 2,000 people, is central to its strategy. The company is upgrading the site with automation, digital tools, and artificial intelligence as part of an investment plan that could total up to US$300 million.

The goal is to raise repair volume in Singapore by 33 percent without expanding the facility's footprint, instead reorganising workflows, reshaping floor space, and automating tasks where efficient.

The site is also piloting "Flight Deck," GE's adaptation of the "Lean" manufacturing approach pioneered by Japanese carmakers and championed by CEO Larry Culp.

"It's not about sprinting at quarter's end to make a Wall Street guide. It is making every hour and every day count," Culp said.

Repairing used parts can help ease supply strains by reducing the need to replace worn components with newly manufactured ones, freeing up parts for new engines. GE says repairs can halve both processing time and costs for airlines.

"Repair can really improve turnaround time … the less time the engine is off the wing, the better," said Iain Rodger, head of GE Aerospace Component Repair Singapore.

One reorganised area handles overhauls of CFM56 turbine nozzles. Turnaround time has improved from 40 days in 2021, and GE is targeting 21 days by 2028. Part of the space is being freed up to develop repair capabilities for newer LEAP engines entering overhaul cycles.

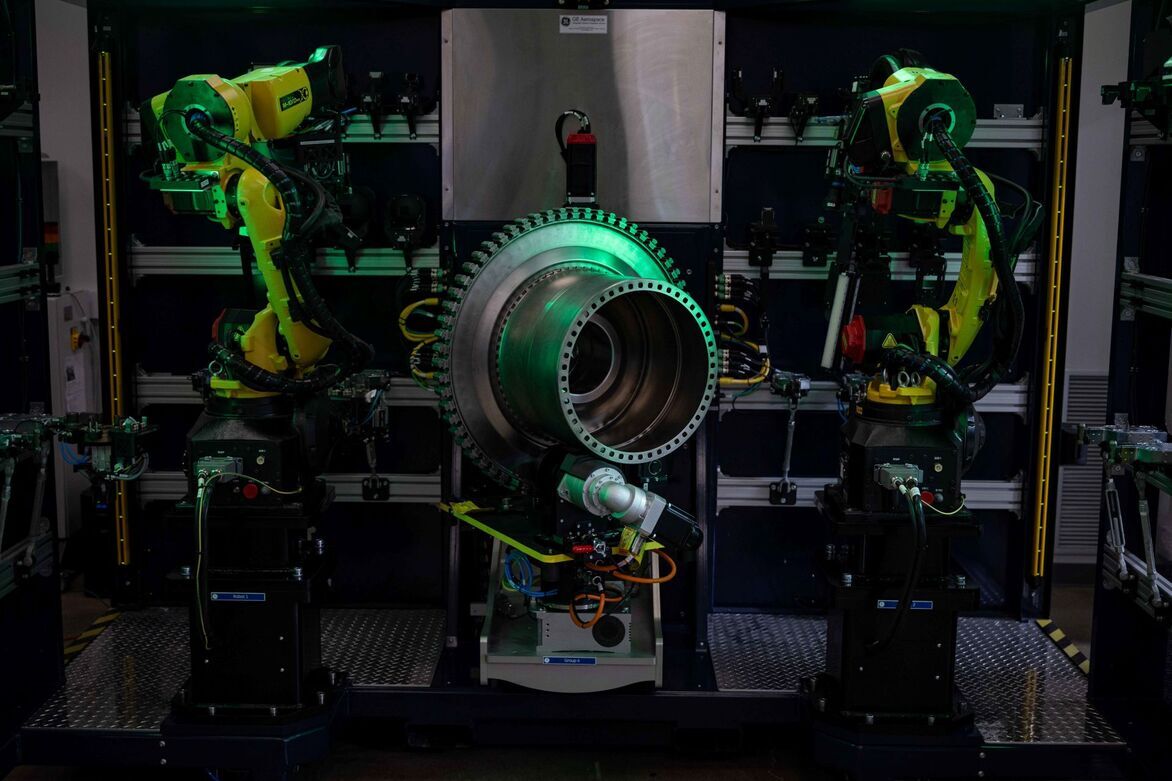

Teaching Robots the Human Touch

Some of the most challenging tasks remain highly manual. Compressor blade blending, reshaping worn metal to precise tolerances, has traditionally relied on technician skill and feel.

"It's really hard to do. (Until now) It is 100 percent manual," said Sinnaiyan.

GE aims to translate that expertise into repeatable robotic processes to reduce dependence on scarce specialised labour and boost throughput.

Even so, repair expansion has limits. Strict quality controls are in place, and analysts note that strong demand for repairs driven by slower new-aircraft production may moderate.

"It is about moving away from firefighting and heroics to a different type of preferred performance," Culp said.

Categories: Singapore news, Southeast Asia news, Breaking Technology news, Breaking Engineering News, Breaking Airlines news, Human Resources news, Breaking Business news.